- #Speaker enclosure design box vs cylinder drivers

- #Speaker enclosure design box vs cylinder driver

- #Speaker enclosure design box vs cylinder free

The math in calculating chamber volume gets a little more complicated, but the build may get simpler with having only one angled side. In this design, only the front board is angled.

#Speaker enclosure design box vs cylinder driver

Notice that the chamber for the midrange driver isn't the full depth of the speaker. Note: the woofer will be ported in all of these design options, even when it isn't shown.

707 value for Qtc for a smooth roll-off at the low end.Ĭalculating box volume and port size for a ported enclosure requires Vas, Fs, Qts, and the cone diameter.

I am going to ignore these results and use one sealed enclosure and one ported enclosure to show the differences between the two.Ī sealed chamber will be used for the mid and a ported enclosure for the woofer.Ĭalculating box volume for a sealed box requires Vas, Fs, & Qts.

#Speaker enclosure design box vs cylinder drivers

The EBP of our midrange and woofer drivers are calculated as:īoth values are well above 90 and call for Ported Enclosures.

The tweeter in our example is already sealed and doesn't require an enclosure.

#Speaker enclosure design box vs cylinder free

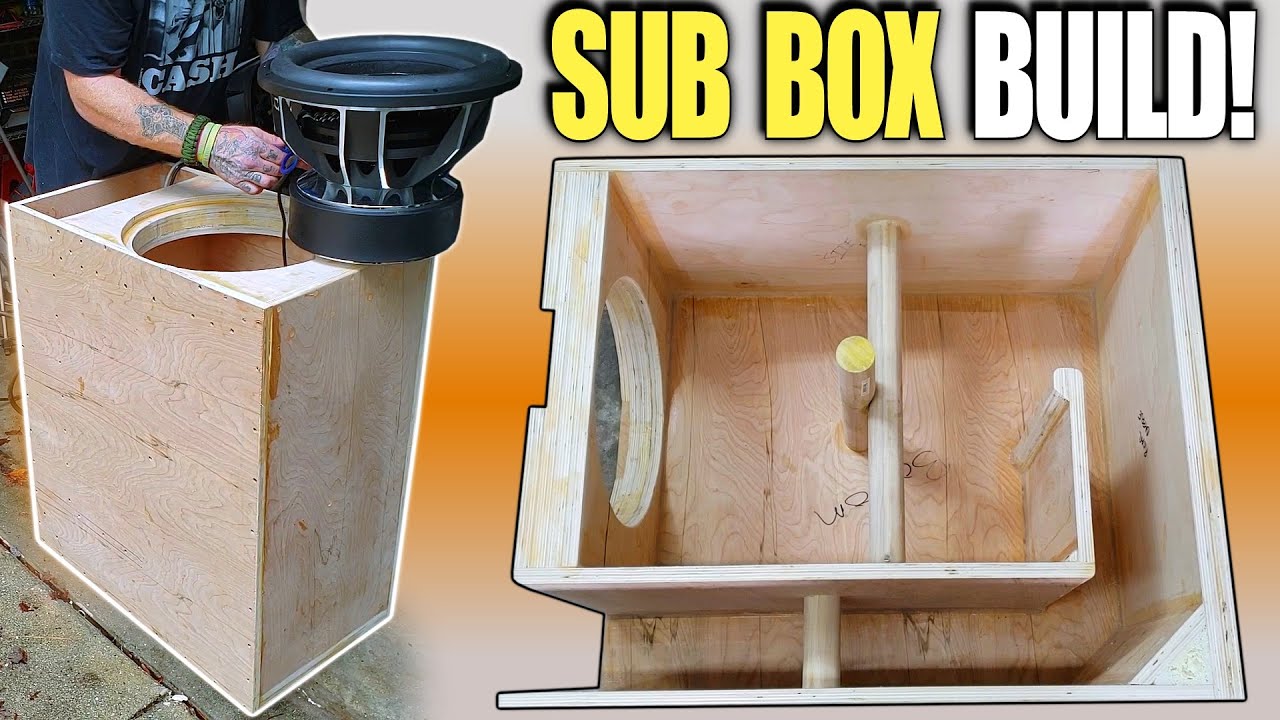

Between 50 & 90 either type would work.Įfficiency Bandwidth Product (EBP) = Free Air Resonance (Fs) / Driver Electrical "Q" (Qes) Above 90~100 and a Ported Enclosure is recommended. If the EBP is less than 50, then a Sealed Enclosure is recommended. Ported calculator uses the formula below. Ported Speaker Box Calculator to determine if a sealed or a ported enclosure should be used. (with specifications provided by the manufacturer) are: The mid is 4" and the woofer is 6.5" in size, but this system is still capable of These 3 drivers might be smaller than what is expected of a typical 3-way system. This design is old and the characteristics of these drivers have since changed and/or been discontinued. The same 3 used on the Crossover Tutorial. You should also review the Speaker Building Guideįor this example, I picked 3 ScanSpeak drivers for a 3-way speaker. This example of a designing a speaker box makes use of many of the calculators found on The braces used are important to reduce vibration and must be fitted properly to enable them to be useful.Designing and Building a Speaker Box Example Though nails can also be used, these can gradually become loose due to the number of vibrations that the subwoofer box can go through. The glue should be a starting point to hold the box together before following it up with screws. To construct subwoofer boxes, you should use glue, screws, and caulk. Wood can also split when screws are used to fasten one piece to another. Natural wood can resonate to the point where it distorts the sound and causes the fasteners to loosen. Though plain wood is cheap and readily available in varying thicknesses, this does not mean that it is always the best option for building a subwoofer box.

Fiberglass is also easy to clean and will not react to temperature and weather. However, fiberglass is not suitable for larger single panels. If you want subwoofer boxes which are strong yet light, fiberglass is a good option to choose. It is also easy to drill to create the air holes required. Birch plywood is commonly used and has been found to work well. If choosing a laminated variety, it is important to make sure that there are no defects present as this can affect the sound and cause a subwoofer box to rattle. It is a material that is lighter than MDF because it is not as dense, but is still sturdy enough to work well. PlywoodĪn effective subwoofer box can be made from plywood. Pick up all you need for and MDF subwoofer box build today. Though it looks similar, it should not be confused with particle board which is not as densely constructed.

0 kommentar(er)

0 kommentar(er)